OEM/ODM services for custom logo electric salt and pepper mills offer restaurants unique opportunities. These services enhance brand identity, streamline operations, and provide a premium dining experience. Establishments procure high-quality, branded kitchen and table accessories. For example, a custom USB Electric Salt and Pepper Grinder or an Electric Stainless Steel pepper mill with light can elevate the dining ambiance. Manufacturers tailor these items to specific aesthetic and functional needs. This directly addresses the desire for differentiation and efficiency within the competitive restaurant industry.

Key Takeaways

- OEM and ODM services help restaurants get custom electric salt and pepper mills.

- OEM means the manufacturer builds products from the restaurant’s own designs.

- ODM means the manufacturer offers existing designs that restaurants can customize.

- Custom mills make a restaurant’s brand stronger and improve the dining experience.

- These mills help staff work faster and more easily.

- Choosing the right partner means checking for good quality, customization options, and fair prices.

- Always make sure the mills meet food and electrical safety rules.

- The process includes talking about ideas, making samples, producing the mills, and shipping them.

Understanding OEM/ODM Services for Restaurant Equipment

Restaurants often seek specialized equipment to enhance their brand and operations. OEM and ODM services provide two distinct pathways for acquiring custom products like electric salt and pepper mills. Understanding these models helps businesses make informed decisions.

What is OEM (Original Equipment Manufacturer)?

OEM refers to a manufacturing model where a company produces goods based on another company’s specific designs and specifications. The client maintains significant control over the product’s technical blueprint and intellectual property ownership.

Manufacturing Based on Buyer’s Design

In an OEM arrangement, the buyer provides the complete design. This includes the appearance, functionality, and specific features of the product. The OEM then manufactures the item according to these precise instructions. This model allows the client to leverage the OEM’s manufacturing capabilities while retaining creative control over the final product.

Full Control Over Design and Features

Clients maintain full control over the product’s design, including its appearance, functionality, and features. They conceptualize and develop all specifications, then contract the OEM to produce the product based on these precise instructions. This allows the client to leverage the OEM’s manufacturing capabilities while retaining creative control. The client focuses on design, quality, and production specifications, ensuring the product aligns perfectly with their vision.

What is ODM (Original Design Manufacturer)?

ODM involves a manufacturer designing and producing a product, which other companies then brand and sell. This model offers a different approach to product acquisition.

Customizing Existing Product Designs

An ODM typically has a portfolio of existing product designs. Clients can select one of these designs and request customizations, such as branding, color changes, or minor feature adjustments. The ODM handles both design and production, giving them more control over the manufacturing process. This streamlines the process, allowing businesses to benefit from the ODM’s comprehensive capabilities from concept to final production.

Faster Time-to-Market and Cost-Effectiveness

ODM is generally more cost-effective than developing a product from scratch because it bypasses the extensive development process. This eliminates the need for new specifications and investments in tooling and molding, thereby reducing costs. ODMs typically offer a more affordable solution as the design and development phases are already complete, essentially providing a ready-made product. This appeals to companies aiming to lower upfront costs and achieve a faster time-to-market.

Why Restaurants Choose OEM/ODM for Mills

Restaurants increasingly turn to OEM/ODM services for their electric salt and pepper mills due to several strategic advantages. These services offer tailored solutions that enhance both the guest experience and operational efficiency.

Brand Consistency and Unique Guest Experience

Custom mills reinforce a restaurant’s brand identity. Branded accessories create a cohesive dining environment, subtly marketing the establishment. A unique, branded mill contributes to a memorable and distinctive dining experience for guests.

Operational Benefits for Staff

OEM/ODM mills also provide practical advantages for staff. Electric mills offer one-handed operation for servers, improving service efficiency. Consistent grinding ensures culinary precision, and durable, high-quality mills reduce maintenance and replacement costs over time.

Benefits of Custom Logo Electric Salt & Pepper Mills

Custom logo electric salt and pepper mills offer restaurants a multifaceted advantage. They significantly contribute to a restaurant’s overall appeal, enhancing both its brand presence and the guest’s dining journey. These specialized tools also streamline daily operations, providing tangible benefits for staff and management.

Enhanced Brand Identity and Recognition

A restaurant’s brand extends beyond its menu and decor. Every element on the table contributes to its identity. Custom logo electric salt and pepper mills play a crucial role in solidifying this brand image.

Reinforcing Brand Image at the Table

Branded mills act as miniature billboards on every table. They subtly communicate the restaurant’s commitment to quality and attention to detail. This consistent branding reinforces the establishment’s identity, making every dining experience uniquely theirs.

Cohesive Dining Environment Creation

These custom accessories contribute to a unified aesthetic. When every item, down to the salt and pepper mills, aligns with the restaurant’s theme, it creates a harmonious and immersive dining environment. This cohesion elevates the overall ambiance, making guests feel more connected to the brand.

Subtle Marketing Through Branded Accessories

Branded mills serve as a form of passive marketing. Guests notice and appreciate these thoughtful touches. They often share their dining experiences on social media, and a distinctive, branded mill can become a memorable part of their photos, extending the restaurant’s reach organically.

Elevated Guest Experience

The dining experience encompasses more than just food; it includes every interaction and sensory detail. Custom logo electric salt and pepper mills significantly enhance this experience for diners.

Premium Feel and Ease of Use for Diners

Guests appreciate the convenience and sophistication of electric mills. The effortless operation provides a premium feel, allowing diners to season their food with ease and precision. This small luxury contributes to a more enjoyable and refined meal. Customers consistently rank tablecloths and crockery as significant atmospheric attributes influencing their satisfaction. Similarly, high-quality table accessories like electric mills contribute to this positive perception.

Adding Perceived Value to the Meal

High-quality, branded table accessories add perceived value to the entire dining experience. In fine dining establishments, the quality of glassware, crockery, cutlery, and other serving items is of the highest standard. Custom mills align with this expectation, signaling to guests that the restaurant invests in every aspect of their comfort and satisfaction. Guests often express satisfaction with the tableware used in restaurants, and custom mills contribute to this positive sentiment.

Memorable and Unique Dining Moments

Small details often create the most lasting impressions. A sleek, easy-to-use electric mill with the restaurant’s logo transforms a mundane act into a memorable moment. These unique touches differentiate the restaurant, encouraging guests to return and recommend it to others.

Operational Efficiency and Convenience

Beyond aesthetics and guest satisfaction, custom electric salt and pepper mills offer significant operational advantages for restaurant staff.

One-Handed Operation for Servers

Electric mills allow for one-handed operation, a critical feature for busy servers. They can efficiently season dishes or offer condiments to guests without juggling multiple items. This improves service speed and reduces the risk of spills or accidents. Modern electric models solve every pain point: one-handed operation while cooking, adjustable coarseness for any recipe, and LED-lit precision for low-light kitchens.

Consistent Grinding for Culinary Precision

Chefs and kitchen staff benefit immensely from the consistent grinding capabilities of electric mills. An electric pepper mill is a modern kitchen tool designed to grind peppercorns effortlessly with the push of a button. Unlike manual grinders, these devices use battery-powered or rechargeable motors to deliver consistent, adjustable coarseness for perfect seasoning every time. These mills are ideal for home cooks and professional chefs who value precision and convenience.

Most electric pepper mills feature adjustable grind settings, allowing you to switch between fine powder and coarse cracks. This versatility ensures the right texture for any dish, from delicate sauces to hearty steaks.

This consistency ensures uniform flavor distribution and culinary precision, which is vital for maintaining dish quality. Adjustable coarseness allows customization from fine powder to coarse cracks, suiting different dishes and personal preferences.

Reduced Maintenance and Replacement Costs

Durable, high-quality electric mills, especially those sourced through OEM/ODM services, are built for commercial use. They withstand the rigors of a busy restaurant environment, reducing the frequency of repairs and replacements. This translates into long-term cost savings and less downtime for essential table accessories. The CoFlavet Electric Pepper Mill, for example, redefines kitchen efficiency with its innovative electric grinding system, delivering consistent results with zero effort.

The Peugeot Elis Sense mechanism brings out the depth of each seasoning by selecting the right grind for your taste. Finely ground pepper enhances spice, while coarser grinds intensify flavor. This mill transforms ordinary meals into gourmet experiences with minimal effort.

Such robust construction and precise mechanisms ensure longevity and consistent performance, minimizing operational interruptions.

Competitive Differentiation

In today’s competitive culinary landscape, restaurants constantly seek ways to stand out. Custom logo electric salt and pepper mills offer a powerful tool for achieving this differentiation. They provide a unique touch that elevates the dining experience beyond just the food.

Setting Your Restaurant Apart

Restaurants distinguish themselves through various elements. Custom electric salt and pepper mills contribute significantly to this effort. They move beyond generic table accessories, showcasing a restaurant’s commitment to detail and quality. A branded mill communicates a clear message: this establishment invests in every aspect of the guest’s journey. This attention to detail creates a memorable impression, making the restaurant unique in the minds of its patrons. It helps forge a distinct identity that competitors cannot easily replicate.

Contributing to a Distinctive Ambiance

The ambiance of a restaurant plays a crucial role in its appeal. Every item on the table contributes to the overall atmosphere. Custom logo electric mills seamlessly integrate into the restaurant’s theme and decor. They enhance the visual appeal of the dining space. For example, a sleek, modern mill complements a contemporary restaurant, while a rustic design suits a farm-to-table establishment. These small, branded details reinforce the restaurant’s chosen aesthetic. They create a cohesive and immersive environment. This careful curation of details makes the dining experience more enjoyable and distinctive for every guest.

Attracting and Retaining Customers

Unique features attract new customers and build loyalty among existing ones. Custom electric salt and pepper mills serve as conversation starters. Guests often notice and appreciate these thoughtful touches. This positive perception encourages word-of-mouth recommendations. Satisfied customers share their experiences, drawing more diners to the restaurant. Furthermore, a distinctive dining experience fosters customer loyalty. When guests feel a restaurant offers something special, they are more likely to return. These branded accessories contribute to that special feeling, helping restaurants build a strong, loyal customer base.

Key Considerations for Choosing an OEM/ODM Partner

Selecting the right OEM/ODM partner is a critical decision for restaurants. This choice directly impacts the quality, functionality, and branding of custom electric salt and pepper mills. Restaurants must evaluate several key factors to ensure a successful partnership and a superior product.

Quality and Durability Standards

High-quality electric mills withstand the demands of a busy commercial kitchen and dining room. Restaurants require products built to last.

Robust Materials for Commercial Use

Commercial-grade electric mills need strong, durable materials. Manufacturers often recommend ceramic or hardened steel for grinding parts. These materials offer excellent wear resistance and maintain smooth grinding over time. For structural components, aluminum or cast iron provide enhanced strength. Overall, stainless steel and ceramic contribute to smooth, strong operation and longevity. These choices ensure the mills endure constant use without frequent breakdowns.

Reliable Motor Mechanisms and Grinders

The internal components of an electric mill are crucial for performance. A reliable motor mechanism ensures consistent power and efficient grinding. High-quality grinders deliver uniform particle size, which is essential for culinary precision. Restaurants should seek partners who use proven, robust internal systems designed for commercial environments.

Warranty and Product Testing Standards

A reputable OEM/ODM partner stands behind its products. They offer clear warranties that cover defects and malfunctions. Furthermore, they adhere to rigorous product testing standards. These tests confirm the mills meet performance, safety, and durability benchmarks before reaching the restaurant. This commitment to quality provides peace of mind and protects the restaurant’s investment.

Customization Options for Branding

Customization is a primary reason restaurants choose OEM/ODM services. The partner’s ability to execute specific branding requirements is paramount.

Logo Placement and Application Methods

Restaurants need various options for displaying their logo. Partners should offer methods like laser engraving, pad printing, or silk-screening. Each method provides a different aesthetic and level of durability. The chosen application method must ensure the logo remains clear and intact through regular use and cleaning.

Color Matching and Material Choices

The aesthetic appeal of the mills must align with the restaurant’s decor. OEM/ODM partners offer extensive choices for body materials and finishes. For example, body materials can range from poplar, pine, and alder to more exotic woods like African or Honduran mahogany. Finishing types include solids, metallics, candies, flakes, and clear coats in satin or gloss. Partners can also provide custom color matching to perfectly integrate the mills into the restaurant’s existing design scheme.

Packaging and Unique Feature Integration

Customization extends beyond the mill itself. Branded packaging enhances the unboxing experience and reinforces brand identity. Partners can also integrate unique features, such as specific LED lighting colors or custom grind settings, to further differentiate the product. These details contribute to a cohesive brand presentation.

Minimum Order Quantity (MOQ) and Pricing

Understanding the financial aspects of an OEM/ODM partnership is essential for budget planning and long-term value.

Understanding MOQ for Restaurant Size

Minimum Order Quantity (MOQ) varies significantly among manufacturers and product types. Restaurants must find a partner whose MOQ aligns with their operational scale. For instance, MOQs for custom items can range widely depending on the material and manufacturing region.

| Fabric Type / Region | Typical MOQ Range | Notes |

|---|---|---|

| Fabric Types | ||

| Cotton (digital print) | 50 – 100 meters | Short runs possible, higher cost |

| Linen | 200 – 300 meters | MOQ lower if greige only |

| Polyester | 500 – 1000 meters | Economical, favored for fast fashion |

| Manufacturing Regions | ||

| China | 300 – 1000 meters | Most flexible for digital prints |

| India | 500 – 2000 meters | Strong in cotton and woven jacquards |

| Italy | 100 – 300 meters | Ideal for luxury fabrics and small batches |

While this table shows fabric MOQs, it illustrates the concept of varying MOQs based on material and region. For electric mills, MOQs often depend on the level of customization and the manufacturer’s production capabilities. Restaurants should discuss their specific needs with potential partners.

Transparent Cost Structures and Value

A reliable partner provides a clear breakdown of all costs. Pricing factors include the base price per unit and potential mould or tooling costs for new designs. Packaging costs, logistics (duties, customs, insurance), and after-sales costs (warranty, replacements) also contribute to the total. Higher MOQs, for example, often lead to lower per-unit costs but require a greater inventory investment. Restaurants should also consider the total cost of ownership, factoring in durability and potential maintenance. The grinding mechanism, material construction (acrylic, wood, stainless steel, glass), and capacity also influence the price.

Long-Term Investment vs. Upfront Cost

Restaurants must balance the initial upfront cost with the long-term value. Investing in high-quality materials and reliable grinding mechanisms, such as ceramic cores, ensures longevity and consistent performance. This reduces the need for frequent replacements. While cheaper options may seem appealing initially, they often lead to higher maintenance and replacement costs over time. A durable, well-made custom mill represents a strategic long-term investment in brand image and operational efficiency.

Lead Times and Logistics Management

Effective lead time and logistics management are paramount when sourcing custom electric salt and pepper mills. Restaurants rely on predictable timelines to manage their operations, especially during new openings or rebranding initiatives. A reliable OEM/ODM partner provides clear communication and efficient processes to ensure timely delivery.

Production Timelines and Delivery Schedules

Production timelines for custom electric salt and pepper mills vary based on order volume and specific customization requirements. For smaller orders, manufacturers often provide quicker turnarounds. For example, a typical lead time for 1 to 300 sets of electric salt and pepper mills is approximately 10 days. Similarly, for orders of 1 to 100 sets, the lead time also stands at about 10 days.

| Quantity (sets) | Lead time (days) |

|---|---|

| 1 – 300 | 10 |

| > 300 | To be negotiated |

| Quantity (sets) | Lead time (days) |

|---|---|

| 1 – 100 | 10 |

| > 100 | To be negotiated |

For larger quantities exceeding these thresholds, the lead time requires negotiation. Customers receive an estimated delivery timeline from sales representatives after sharing detailed requirements. This ensures the manufacturer can accurately assess the scope of work and provide a realistic schedule.

Supply Chain Reliability and Efficiency

A robust supply chain is crucial for consistent production and delivery. However, the global supply chain faces numerous challenges that can impact lead times and costs.

- Raw Materials and Component Construction: Lingering raw material shortages, fewer workers in mines and manufacturing, and transportation issues in manufacturing countries can delay initial production.

- Import Shipping and Logistics: Port congestion, a shortage of container chassis, backed-up rail stations, and a scarcity of truck drivers create significant bottlenecks in international shipping.

- Equipment Assembly: Smaller workforce pools, social distancing protocols limiting capacity, and manufacturing lines stopping or starting based on component arrival can hinder assembly. Built equipment often waits for specific components.

- Last-Mile Delivery: Truck driver shortages and increased pressure on delivery services due to e-commerce growth affect the final stage of delivery.

Beyond these operational hurdles, broader economic and geopolitical factors also influence logistics:

- Increased Expenses: Rising fuel costs, increased warehousing prices, and geopolitical events affecting ocean and air freight drive higher transportation and logistics expenses.

- Regulatory Complexities: Complex trade regulations, varying customs policies, tariffs, and trade agreements cause shipment delays and operational complications.

- Geopolitical Tensions: Political unrest, trade wars, and economic sanctions disrupt trade routes and supply chains.

- Environmental Pressures: Stringent emission norms necessitate investments in cleaner fuels and green practices, potentially adding to costs and logistical considerations.

OEM/ODM partners must demonstrate resilience and adaptability in navigating these complexities. They should have contingency plans for potential disruptions, ensuring a smoother process for their clients.

Meeting Opening or Rebranding Deadlines

Timely delivery of custom electric salt and pepper mills is critical for restaurants, especially when planning a new opening or a rebranding event. Delays in receiving essential equipment can disrupt schedules, incur additional costs, and negatively impact a restaurant’s launch or relaunch. Precise scheduling is crucial for installations, as delays can lead to significant costs if plumbers and electricians wait for equipment. Dynamic changes in customer demands create pressure for timely product delivery. Last-minute changes in delivery requirements are common, often necessitating rapid investigation of alternate shipping methods to address capacity constraints. A reliable OEM/ODM partner understands these pressures and works proactively to meet agreed-upon deadlines, ensuring the restaurant can open or rebrand as planned.

Certifications and Compliance

Ensuring custom electric salt and pepper mills meet relevant certifications and compliance standards is non-negotiable. These standards guarantee product safety, legality, and quality, protecting both the restaurant and its customers.

Food Safety Standards (e.g., FDA)

Electric salt and pepper mills come into direct contact with food. Therefore, they must comply with stringent food safety standards. In the United States, the Food and Drug Administration (FDA) sets guidelines for materials that contact food. Manufacturers must use food-grade materials for all components that touch salt, pepper, or other spices. This prevents contamination and ensures the safety of the food served to diners. Restaurants should always verify that their OEM/ODM partner adheres to these critical regulations.

Electrical Safety Regulations (e.g., CE, RoHS)

As electric devices, these mills must also meet electrical safety regulations. The CE mark indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area. RoHS (Restriction of Hazardous Substances) compliance restricts the use of specific hazardous materials in electrical and electronic products. These certifications confirm the product’s electrical components are safe for use in a commercial environment, minimizing risks of electrical hazards. A reputable manufacturer provides documentation for these essential certifications.

Ensuring Product Legality and Safety

Compliance with food safety and electrical safety standards ensures the product’s legality and overall safety. This protects the restaurant from potential liabilities and ensures customer well-being. A diligent OEM/ODM partner conducts thorough quality assurance testing throughout the manufacturing process. They verify that each mill meets all required certifications before shipment. This commitment to compliance reflects a manufacturer’s dedication to quality and responsibility, providing restaurants with confidence in their custom-branded equipment.

The OEM/ODM Process: From Concept to Delivery

The journey from an initial idea to a finished product involves several critical stages in OEM/ODM manufacturing. This structured process ensures the final electric salt and pepper mills meet a restaurant’s exact specifications and quality expectations.

Initial Consultation and Design Brief

The process begins with a thorough discussion between the restaurant and the OEM/ODM partner. This initial consultation establishes the project’s foundation.

Defining Restaurant Needs and Aesthetic

Restaurants clearly define their specific needs and desired aesthetic for the custom mills. This includes the restaurant’s brand identity, its target audience, and the overall dining environment. A comprehensive business overview helps the manufacturer understand the company’s mission, vision, and unique differentiators.

Discussing Functional Requirements

Functional requirements are crucial for electric salt and pepper mills. The discussion covers desired features such as battery type, motor power, grind settings, and material preferences. An initial design brief should outline the project’s goals and objectives, including measurable success metrics. It also identifies the target market, understanding their demographics, habits, and problems the product aims to solve.

Idea Generation and Concept Development

With a clear understanding of needs, the OEM/ODM partner begins idea generation and concept development. This stage considers competitor analysis to understand market positioning and industry stylistic conventions. The brief also includes project deliverables, timelines, and budget constraints. It details existing assets like style guides or previous designs, ensuring a cohesive development process.

Prototyping and Sample Approval

After concept development, the manufacturing partner moves to prototyping. This stage allows for tangible evaluation and refinement.

Creation of Physical Samples

Manufacturers create physical samples based on the approved design brief. These initial samples, often called Proto 1, check basic size, shape, and functionality. Subsequent samples, Proto 2 and Proto 3+, incorporate final materials and features, refining the design until it receives 100% approval.

Review and Feedback on Prototypes

Restaurants thoroughly review these prototypes. They provide detailed feedback on design, functionality, and overall feel. This iterative process ensures the product aligns perfectly with expectations.

Ensuring Design and Functionality Match Expectations

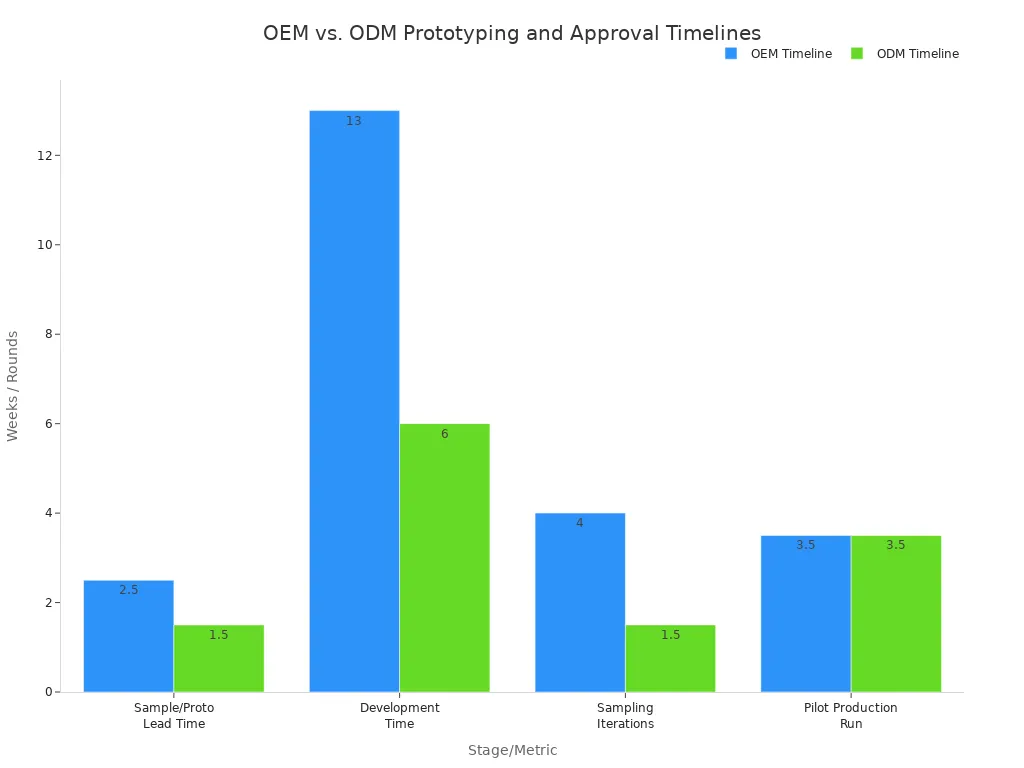

The OEM/ODM process for samples involves several iterations to guarantee the final product meets all requirements. The sample/proto lead time for OEM typically takes 2-3 weeks, while ODM usually takes 1-2 weeks. Development time can range from 10-16 weeks for OEM and 4-8 weeks for ODM.

| Stage/Metric | OEM Timeline | ODM Timeline |

|---|---|---|

| Sample/Proto Lead Time | 2-3 weeks | 1-2 weeks |

| Development Time | 10-16 weeks | 4-8 weeks |

| Sampling Iterations | 3-5 rounds | 1-2 rounds |

| Pilot Production Run | 3-4 weeks | 3-4 weeks |

After final sample approval, a pilot production run of 50–100 units ensures consistency before full-scale manufacturing.

Production and Quality Control

Once the restaurant approves the final prototype, the OEM/ODM partner moves into full-scale production. This phase emphasizes precision and adherence to standards.

Manufacturing with Strict Standards

Manufacturers produce the custom electric salt and pepper mills using strict quality standards. They employ specialized machinery and skilled labor to ensure consistency across all units. This stage focuses on efficient and accurate assembly.

In-Process and Final Quality Checks

Throughout the production process, the manufacturer conducts rigorous quality checks. These include in-process inspections at various stages and a comprehensive final quality control assessment. These checks identify and rectify any deviations from the agreed-upon specifications.

Adherence to Agreed Specifications

The OEM/ODM partner ensures every mill adheres precisely to the agreed-upon design, functional requirements, and material specifications. This commitment to detail guarantees the restaurant receives a high-quality, branded product that meets all expectations.

Packaging and Shipping Logistics

After manufacturing, the custom electric salt and pepper mills require careful packaging and efficient shipping. This final stage ensures products arrive safely and on time at restaurant locations. A reliable OEM/ODM partner manages these critical logistics.

Custom Branded Packaging Options

Restaurants can extend their brand identity to the packaging itself. OEM/ODM partners offer various custom branded packaging options. This includes boxes featuring the restaurant’s logo, specific colors, or unique designs. Branded packaging enhances the unboxing experience and reinforces the restaurant’s commitment to quality. It also creates a cohesive brand presentation from the moment the product arrives.

Secure and Efficient Logistics

Secure and efficient logistics are paramount for delivering custom electric mills. Manufacturers carefully evaluate the items they ship, considering factors like fragility, weight, and resistance to elements. They design custom industrial packaging that precisely fits the merchandise. This reduces weight, minimizes shipping costs, and prevents shifting or damage during transit. Choosing appropriate packaging materials is also crucial. Options include cardboard, plastic, wood, and steel, each offering different benefits in terms of strength and durability.

To ensure maximum protection, manufacturers often use corner protectors to minimize impact damage, especially for larger devices. They also utilize sealed and reinforced packaging to ensure tamper resistance and security. Temperature and climate considerations are vital for electronics. Manufacturers avoid storing mills in hot or humid environments before shipping. They may use insulated liners or desiccants for moisture control. Selecting carriers with good handling practices and using “fragile” labels or “this side up” stickers further safeguards the products. Optimizing packaging for dimensional weight pricing helps avoid extra fees. A packaging professional often collaborates with the manufacturer to design custom protective packaging and ensure compliance with federal regulations.

Timely Delivery to Restaurant Locations

Timely delivery is essential for restaurants, especially when coordinating new openings or rebranding efforts. Restaurants rely on their OEM/ODM partner to manage the supply chain effectively. This includes choosing reliable shipping partners with expertise in handling sensitive shipments. These partners offer services like tracking and monitoring capabilities. They also provide full equipment coverage. Manufacturers implement secure labeling and documentation, clearly marking packages with contents and special handling instructions. They include detailed packing lists, invoices, and shipping labels in waterproof envelopes. Planning for contingencies is also vital. This involves developing a comprehensive plan for delays, damage, or loss. It includes contact details for all involved parties. This proactive approach ensures the restaurant receives its custom mills as scheduled, supporting smooth operations and successful launches.

Customizing Your USB Electric Salt and Pepper Grinder

Restaurants can significantly enhance their brand and guest experience by customizing a USB Electric Salt and Pepper Grinder. This process involves tailoring design elements, branding, and technical specifications to meet specific operational and aesthetic needs.

Design Elements for USB Electric Mills

The physical design of a USB Electric Salt and Pepper Grinder plays a crucial role in its functionality and appeal. Thoughtful design ensures user satisfaction and seamless integration into the dining environment.

Ergonomics and User-Friendly Design

Ergonomic considerations are paramount for a USB Electric Salt and Pepper Grinder. Designs often feature easy one-handed operation, which is ideal for multitasking servers. Ergonomic grips provide comfort, benefiting users with limited hand strength. Lightweight designs further enhance ease of use. Adjustable coarseness settings and built-in LED lights contribute to seasoning accuracy. Transparent chambers allow easy monitoring of spice levels. Many models also offer one-touch or gravity-activated operation for ultimate convenience.

Material Selection for Durability and Aesthetics

Choosing the right materials balances durability with aesthetic appeal. Stainless steel offers a sleek, modern look and excellent resistance to corrosion. High-quality plastics can provide vibrant color options and reduce weight. Ceramic grinding mechanisms ensure longevity and consistent performance. The material choice should align with the restaurant’s interior design and brand image.

LED Lighting and Grind Setting Indicators

LED lighting on electric mills serves a practical purpose. It illuminates the food during seasoning, ensuring precise application, especially in dimly lit dining areas. Grind setting indicators, whether visual or tactile, allow users to easily select their preferred coarseness. These features enhance the user experience and add a touch of sophistication.

Branding Your USB Electric Salt and Pepper Grinder

Branding a USB Electric Salt and Pepper Grinder transforms a functional item into a powerful marketing tool. Customization options allow restaurants to reinforce their identity.

Logo Engraving vs. Printing Options

Restaurants have several options for applying their logo. Laser engraving offers a permanent, sophisticated finish, ideal for metal surfaces. Pad printing or silk-screening provides more flexibility for color and placement on various materials. The chosen method should reflect the desired brand aesthetic and durability requirements.

Color Customization to Match Decor

Color customization ensures the mills seamlessly integrate with the restaurant’s decor. OEM/ODM partners can match specific brand colors or provide a range of finishes. This attention to detail creates a cohesive and polished dining environment.

Unique Packaging for Retail or Gifting

Custom packaging extends the branding experience. Restaurants can use branded boxes for presentation or even offer the mills for retail. Unique packaging enhances perceived value and makes the mills suitable for gifting or promotional purposes.

Technical Specifications and Performance

The technical specifications of a USB Electric Salt and Pepper Grinder directly impact its performance and reliability. Restaurants must consider these details for optimal operation.

Battery Life and Charging Efficiency

Battery life and charging efficiency are critical for commercial use. A typical USB Electric Salt and Pepper Grinder might feature a 2000 mAh battery capacity. This often provides 15-20 grinding sessions per full charge, depending on grind duration. Charging usually takes approximately 2-3 hours for a full charge. Efficient charging ensures the mills are always ready for service.

Motor Power and Grinding Consistency

Motor power dictates grinding efficiency and consistency. A motor with 200W power ensures robust performance. Some DC motors are rated for over 600 hours of operation, or more than 1,200 kg of coffee at a filter grind setting, indicating high durability. Consistent grinding is essential for culinary precision.

Adjustable Coarseness Settings

Adjustable coarseness settings allow diners and chefs to customize seasoning. This versatility caters to different dishes and personal preferences. A well-designed mechanism provides smooth and precise adjustments.

Ensuring Compliance for USB Electric Grinders

Restaurants must prioritize compliance when sourcing a USB Electric Salt and Pepper Grinder. Adhering to relevant standards guarantees product safety, legality, and quality. This protects both the establishment and its customers.

Electrical Safety Certifications (CE, RoHS)

Electric devices require specific certifications to ensure safe operation. The CE mark indicates a product conforms with health, safety, and environmental protection standards for products sold within the European Economic Area. Manufacturers obtain this certification. RoHS (Restriction of Hazardous Substances) compliance restricts the use of specific hazardous materials in electrical and electronic products. This includes lead, mercury, and cadmium. These certifications confirm the USB Electric Salt and Pepper Grinder’s electrical components are safe for use in a commercial environment. They minimize risks of electrical hazards. A reputable manufacturer provides documentation for these essential certifications. Restaurants should always verify these credentials.

Food-Grade Material Verification

A USB Electric Salt and Pepper Grinder comes into direct contact with food. Therefore, it must comply with stringent food safety standards. Manufacturers must use food-grade materials for all components touching salt, pepper, or other spices. This includes the grinding mechanism and the spice chambers. Food-grade materials prevent contamination and ensure the safety of the food served to diners. Restaurants should always verify their OEM/ODM partner adheres to these critical regulations. This verification often involves material safety data sheets or third-party testing reports.

Quality Assurance Testing

Rigorous quality assurance testing is essential for any commercial kitchen equipment. Manufacturers conduct comprehensive tests throughout the production process. These tests verify the USB Electric Salt and Pepper Grinder meets performance, durability, and safety benchmarks. They include checks for motor function, battery life, grinding consistency, and structural integrity. In-process inspections occur at various stages. A final quality control assessment ensures the product adheres to all agreed-upon specifications. This commitment to testing provides peace of mind. It protects the restaurant’s investment and ensures consistent operation.

OEM/ODM services for custom logo electric salt and pepper mills offer restaurants a strategic investment. These services elevate a brand, enhance the dining experience, and optimize daily operations. Partnering with the right manufacturer ensures high-quality, branded accessories. These unique items reflect a restaurant’s distinct identity. They consistently leave a lasting impression on every guest.

FAQ

What is the difference between OEM and ODM services?

OEM (Original Equipment Manufacturer) produces goods based on the buyer’s specific designs. The buyer retains full design control. ODM (Original Design Manufacturer) offers existing product designs. Buyers customize these designs, leading to faster time-to-market and cost-effectiveness.

Why should restaurants invest in custom logo electric mills?

Custom mills enhance brand identity and recognition. They elevate the guest experience, offering a premium feel. These mills also improve operational efficiency for staff. Ultimately, they provide a competitive differentiation in the market.

What customization options are available for branding?

Restaurants can customize logo placement and application methods, such as engraving or printing. They can also choose specific colors to match their decor. Unique packaging options are available for retail or gifting purposes.

What is a Minimum Order Quantity (MOQ)?

MOQ is the smallest number of units a manufacturer will produce in a single order. It varies based on the product, materials, and customization level. Restaurants should discuss their needs with potential partners to find a suitable MOQ.

How long does the OEM/ODM process typically take?

The process duration varies. Initial consultation and design brief take time. Prototyping and sample approval can take several weeks. Production and delivery timelines depend on order volume and complexity. Manufacturers provide estimated schedules.

What certifications are important for electric salt and pepper mills?

Food safety standards, like FDA compliance, are crucial for materials contacting food. Electrical safety regulations, such as CE and RoHS, ensure safe operation. These certifications guarantee product legality and safety for commercial use.

Can restaurants request samples before placing a large order?

Yes, reputable OEM/ODM partners provide samples. This allows restaurants to review and approve the design and functionality. Sample approval ensures the final product meets all expectations before full-scale production begins.

Post time: Nov-03-2025